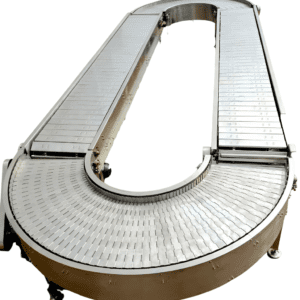

Curved conveyor ensures smooth and efficient transfer of products around corners, supporting continuous flow in material handling systems. Its robust structure provides reliable operation and reduces downtime.

Widely used in factories, logistics centers, and warehouses, the conveyor optimizes layout flexibility and improves workflow.

Key Advantages:

Customizable Design: We offer flexible customization services, designing the ideal curved conveyors and conveyor belts based on your space limitations, material types, and transportation needs.

Multiple Turning Angles: Whether 90°, 180°, or 360° turns, our conveyors ensure smooth and stable material handling, meeting the needs of tight spaces or complex layouts.

Efficiency and Reliability: Our curved conveyors ensure smooth transitions for materials at various angles, preventing jams and material damage. The design focuses on high efficiency, enhancing overall production line performance while maintaining stability and durability.

Strong Adaptability: Easily integrated into existing conveyor systems, our products work seamlessly with other conveyor equipment, achieving a complete automated logistics process.

Optimized Material Flow Paths: By designing suitable curved layouts, we can optimize material transport routes, reduce unnecessary handling distances, and improve overall material flow efficiency.

Customizable radius, width, and angle allow seamless integration with straight conveyors and automated equipment. Its modular design simplifies installation, cleaning, and maintenance.

Curved conveyor enhances efficiency, space utilization, and reliability, making it an essential solution for modern logistics and industrial environments.